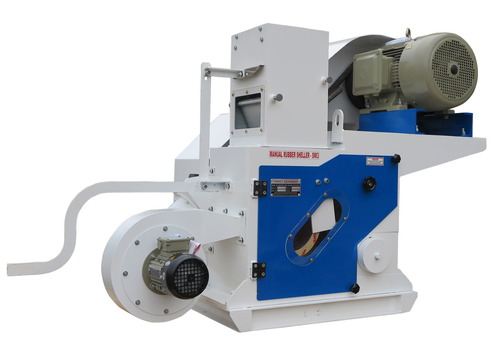

Vibro Pneumatic Rubber Sheller

MOQ : 1 , , Piece

Vibro Pneumatic Rubber Sheller Specification

- Density

- 1.14 Gram per cubic centimeter(g/cm3)

- Material

- Rubber with pneumatic components

- Part Type

- Shelling Roll

- Ash %

- Less than 1%

- Natural Rubber

- Premium natural rubber blend

- Surface Finish

- Smooth

- Weight

- 750 Kilograms (kg)

- Compression Ratio

- Superior compression ratio for even shelling

- Rubber Type

- Grain processing rubber

- Diameter

- 10 Meter (m)

- Volatile Matter (%)

- Low

- Color

- Blue and White

- Thermal Conductivity

- Low

- Tolerance

- 0.5 mm

- Components

- Rubber sheller roll, pneumatic vibration system, mounting fixtures

- Size

- Standard

- Resistance level

- Excellent to abrasion and wear

- Temperature Resistance

- Up to 70C

- Tensile Strength

- High tensile rubber for long life

- Water Absorption

- Low

- Feature

- Low maintenance, high efficiency and consistent shelling performance

- Usage & Applications

- Used in rice mills and grain processing industry for shelling and dehusking operations

- Flame Resistance Level

- Standard

- Thickness

- 12 mm

- Style

- Vibro Pneumatic

- Product Type

- Rubber Sheller

- Nitrogen Content (%)

- Negligible

- Length

- 2280

- Hardness

- 655 Shore A

- Mounting Type

- Flange Mount

- Shelling Efficiency

- Up to 99%

- Adhesion

- Strong rubber-metal adhesion

- Noise Level

- Low noise operation

- Packaging Type

- Protective wooden crate

- Frequency

- 50 Hz

- Operating Voltage

- 220-240 V, single phase

- Roll Speed

- Variable, up to 1200 RPM

Vibro Pneumatic Rubber Sheller Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 , , Piece Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, South America, Western Europe, Asia, Central America

- Main Domestic Market

- All India

About Vibro Pneumatic Rubber Sheller

Technical Specifications

| Automation Grade | Manual, Automatic, Semi-Automatic |

| Brand | Perfect |

| Capacity | 40-80 ton/day, 4 MT on Paddy |

| Material | MS and Iron |

| Power required | 12.5 HP x 1440 |

| Type | Vibro Pneumatic Sheller |

| Rubber Roll Size | 10" DMR |

High-Efficiency Shelling for Grain Processing

With up to 99% shelling efficiency, the Vibro Pneumatic Rubber Sheller ensures superior output in rice mills and other grain processing industries. Its variable roll speed empowers operators to adjust performance for distinct types of grains, promoting precise dehusking while minimizing loss and maximizing productivity.

Durable Design and Reliable Components

Built using a premium natural rubber blend and advanced pneumatic vibration systems, this sheller delivers long-lasting durability with minimal maintenance. Low ash content, excellent temperature resistance, and a strong adhesion between rubber and metal promote extended service life amid challenging industrial environments.

Safe, Simple Installation and Operation

Mounting with a flange system and packaged in protective wooden crates, installation is straightforward. The single-phase voltage (220-240 V) and streamlined controls make operation easy while ensuring low noise and consistent performance, prioritizing both operator comfort and worksite safety.

FAQ's of Vibro Pneumatic Rubber Sheller:

Q: How does the Vibro Pneumatic Rubber Sheller enhance shelling efficiency in rice mills?

A: The sheller is engineered to deliver up to 99% shelling efficiency through its superior rubber roll technology, variable speed adjustment, and pneumatic vibration system. This ensures thorough dehusking and minimal grain breakage, improving productivity and product quality in rice mills.Q: What are the benefits of strong rubber-metal adhesion for sheller performance?

A: Strong rubber-metal adhesion ensures the roll remains structurally sound during high-speed operation. This enhances the sheller's durability, reliability, and consistent shelling performance, especially under demanding industrial conditions.Q: Where is the Vibro Pneumatic Rubber Sheller typically used?

A: This sheller roll is primarily used in rice mills and grain processing facilities across India for shelling and dehusking operations, thanks to its robust construction and superior efficiency.Q: What makes the installation process straightforward for this sheller?

A: Equipped with a flange mounting type and shipped in a protective wooden crate, the sheller can be easily installed and securely positioned. Clear mounting fixtures and standard sizing further expedite the installation procedure for operators.Q: What kind of maintenance is required for the Vibro Pneumatic Rubber Sheller?

A: Minimal maintenance is needed due to its high material quality, abrasion resistance, and low ash content. Regular inspection for wear and proper cleaning will maintain its shelling efficiency and prolong its service life.Q: When should the shelling roll be replaced or serviced?

A: The shelling roll should be inspected periodically for any signs of excessive wear, reduction in efficiency, or damage. Replacement is recommended if the sheller fails to maintain optimal shelling efficiency or exhibits significant surface degradation.Q: How does the sheller's low noise operation benefit users?

A: Low noise operation creates a more comfortable working environment, reducing auditory strain on operators and contributing to overall workplace safety, especially during prolonged rice and grain processing hours.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Rubber Sheller Category

Pneumatic Rubber Sheller

Minimum Order Quantity : 1 , , Piece

Style : Cylindrical Rollers

Product Type : Rubber Sheller

Thickness : 1525 mm

Flame Resistance Level : Basic

Hardness : 855 Shore A

Manual Rubber Sheller

Minimum Order Quantity : 1 , , Piece

Style : Manual

Product Type : Rubber Sheller

Thickness : 25 mm (apprx. for roller)

Flame Resistance Level : Nonflame retardant

Hardness : Medium

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free