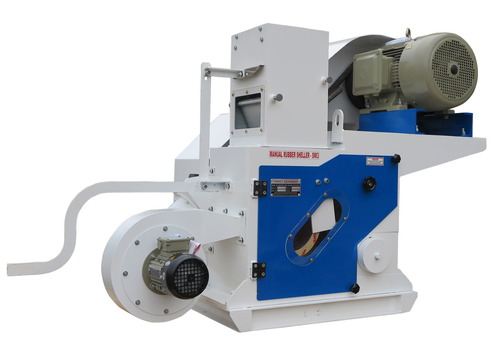

Manual Rubber Sheller

Manual Rubber Sheller Specification

- Density

- Gram per cubic centimeter(g/cm3)

- Style

- Manual

- Product Type

- Rubber Sheller

- Size

- Standard

- Natural Rubber

- Yes, components may include natural rubber

- Thermal Conductivity

- Standard for rubber-metal assemblies

- Thickness

- 25 mm (apprx. for roller)

- Color

- Blue and White

- Weight

- 440 Kilograms (kg)

- Part Type

- Manual Sheller

- Hardness

- Medium

- Temperature Resistance

- Up to 70C

- Material

- Mild Steel body, Rubber rolling parts

- Feature

- Manually operated, robust frame, easy maintenance

- Components

- Hand wheel, rubber rollers, feeding tray, frame, discharge section

- Diameter

- 350 mm (roller)

- Resistance level

- Good wear resistance

- Water Absorption

- Low

- Tolerance

- 2 mm

- Tensile Strength

- High, suitable for agricultural use

- Usage & Applications

- Used for shelling rubber seeds or dehusking processes in agriculture and rubber industries

- Surface Finish

- Painted and powder coated for corrosion resistance

- Compression Ratio

- Optimized for rubber shelling efficiency

- Width

- Approx. 900 mm

- Length

- 2280 Millimeter (mm)

- Rubber Type

- Natural & Synthetic rubber (rollers)

- Flame Resistance Level

- Non-flame retardant

- Feeding Method

- Manual feed via tray

- Roller Type

- Dual grooved rubber rollers

- Discharge Style

- Bottom drop collection tray

- Operation Method

- Manual hand crank

- Noise Level

- Low

- Maintenance

- Simple, tool-less maintenance access

- Mobility

- Fitted with base legs for floor mounting

- Safety Features

- Protective covers over moving parts

- Lubrication Points

- Provided for smooth operation

- Frame Material

- Heavy duty MS structural frame

- Capacity

- Approx. 350-400 kg/hr (seed throughput)

- Corrosion Resistance

- Yes, via painted surface

Manual Rubber Sheller Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 , , Piece Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Manual Rubber Sheller

Owing to our expertise in this field, we are regarded to be one of the most excellent manufacturers and suppliers of Manual Rubber Sheller. Provided sheller is manufactured using quality-approved components and sophisticated methodology under the strict vigilance of our seasoned professionals. Offered sheller is widely demanded for the de-husking of raw and steamed rice. We offer this Manual Rubber Sheller in several designs and technical specifications at reasonable prices to the clients.

Features:

- Sturdy construction

- High operational life

- Standard F2 rubbers

- Can workup to 4 TPH on paddy

- Suitable forraw, Steamand Boiled paddy

- Power Required: 10HPx960 or 12.5HPx1440

Technical Specifications

|

Brand |

Perfect Equipments |

|

Capacity |

3MT on Paddy |

|

Power Required |

10HP * 1440 |

|

Suitable For |

Raw, Steam and Boiled paddy |

|

Type |

Manual Sheller |

|

Rubber Roll Size |

10" DMR |

Versatile Design & Robust Construction

Crafted with a heavy-duty MS structural frame and fitted with dual grooved rubber rollers, this manual sheller ensures high tensile strength and excellent wear resistance. Its painted and powder-coated finish enhances corrosion resistance, making it suitable for demanding agricultural environments.

User-Friendly Operation & Maintenance

Manual operation through an easy-to-use hand crank and tool-less maintenance access means operators enjoy simple, uninterrupted usage. Key lubrication points help ensure smooth, long-term function, while protective covers offer enhanced safety during use.

FAQs of Manual Rubber Sheller:

Q: How does the manual rubber sheller operate?

A: The sheller is operated by turning a manual hand crank, which powers the dual grooved rubber rollers. Seeds are fed manually via the tray, processed by the rollers, and the shelled product is collected in a bottom drop tray.Q: What types of seeds or products can be processed with this sheller?

A: This sheller is primarily designed for rubber seed dehusking, but it can also be used for similar shelling or dehusking requirements in agriculture, thanks to its robust frame and optimized compression ratio.Q: Where is this rubber sheller typically used?

A: The manual rubber sheller is ideally suited for farms, agricultural processing facilities, and rubber industry operations, especially where moderate capacity and robust manual equipment are needed.Q: What are the benefits of using a manual rubber sheller?

A: Key benefits include high durability, low noise operation, easy maintenance, corrosion resistance, enhanced safety features, and reliable performance in processing up to 400 kg of seeds per hour.Q: What steps are involved in the shelling process?

A: Operators load seeds into the feeding tray, turn the hand crank to activate the rollers, and collect the shelled material from the discharge tray at the bottom. Regular lubrication and periodic surface cleaning help maintain peak performance.Q: How does the sheller ensure operator safety?

A: Protective covers are fitted over all moving parts to minimize direct contact, and the solid base legs provide stable floor mounting to prevent accidental movement during operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Sheller Category

Pneumatic Rubber Sheller

Minimum Order Quantity : 1 , , Piece

Usage & Applications : Used in rice mills for dehusking and removing husk from grains

Surface Finish : Polished/Smooth

Compression Ratio : Medium

Length : 2280 Meter (m)

Rubber Type : Pneumatic Rubber

Vibro Pneumatic Rubber Sheller

Minimum Order Quantity : 1 , , Piece

Usage & Applications : Used in rice mills and grain processing industry for shelling and dehusking operations

Surface Finish : Smooth

Compression Ratio : Superior compression ratio for even shelling

Length : 2280

Rubber Type : Grain processing rubber

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS