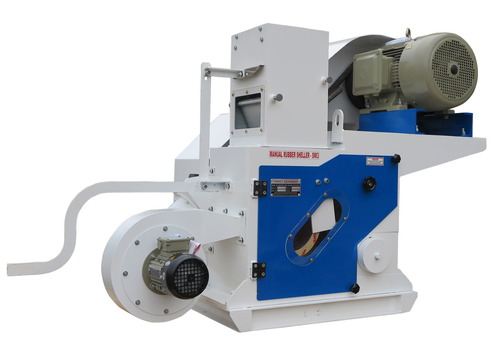

Pneumatic Rubber Sheller

MOQ : 1 , , Piece

Pneumatic Rubber Sheller Specification

- Natural Rubber

- Yes

- Diameter

- 10 Meter (m)

- Color

- White and Blue

- Flame Resistance Level

- Basic

- Thickness

- 15-25 mm

- Usage & Applications

- Used in rice mills for dehusking and removing husk from grains

- Rubber Type

- Pneumatic Rubber

- Temperature Resistance

- Up to 90C

- Width

- Customized as per requirement

- Nitrogen Content (%)

- <0.2%

- Product Type

- Rubber Sheller

- Compression Ratio

- Medium

- Hardness

- 855 Shore A

- Part Type

- Sheller Roller

- Tolerance

- 0.2 mm

- Tensile Strength

- 16-18 MPa

- Ash %

- <1.0%

- Water Absorption

- 0.5%

- Volatile Matter (%)

- 1.2% Max

- Thermal Conductivity

- Low

- Resistance level

- High abrasion and tear resistance

- Size

- Standard/Customized

- Style

- Cylindrical Rollers

- Material

- Natural & Synthetic Rubber Blend

- Weight

- 440 Kilograms (kg)

- Surface Finish

- Polished/Smooth

- Length

- 2280 Meter (m)

- Components

- Roller body, Rubber covering, End flanges

- Density

- 1.25 Gram per cubic centimeter(g/cm3)

- Feature

- Wear-resistant, Smooth Surface, Non-Toxic

- Grip

- Optimized for rice grain handling

- Brand Compatibility

- Suitable for most standard pneumatic rice sheller machines

- Noise Level

- <70 dB during operation

- Sheller roller life expectancy

- Up to 5500 operational hours

- Packaging

- Wooden crate or reinforced carton

- Installation

- Easy fitting with standard sheller assemblies

- Usage Environment

- Dry and clean grain processing areas

- Rotational Speed

- Up to 1500 rpm

Pneumatic Rubber Sheller Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 , , Piece Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, Eastern Europe, Middle East, Africa, South America, Central America

- Main Domestic Market

- All India

About Pneumatic Rubber Sheller

Take advantage of this prodigious Pneumatic Rubber Sheller, expertly crafted for unrivaled rice grain dehusking in mills. Grab the opportunityending soonto equip your facility with champion-grade sheller rollers featuring up to 5,500 operational hours and a remarkable noise level below 70 dB. Installation is seamless into standard sheller assemblies, and the optimized grip ensures precise rice processing in dry, clean environments. Packaged securely in a wooden crate or reinforced carton, these wear-resistant, non-toxic rollers are suitable for most pneumatic sheller machines. Choose from standard or customized specifications for uncompromised performance.

Application and Usage Guidance

The Pneumatic Rubber Sheller is designed for use exclusively in dry and clean grain processing areas. Direction of use involves fitting the sheller roller into standard rice mill assemblies, enabling reliable dehusking and husk removal. Usage type is continuous, supporting demanding operational cycles in milling plants. Its area of application includes rice mills, grain processing factories, and agro-industrial environments requiring optimized rice grain handling for superior yield and quality.

FOB Port, Payment, and Domestic Shipping Details

All shipped goods are dispatched from major Indian FOB ports. Shipment rates are determined by quantity, packaging choice, and consignment size. Payment terms include advance payment or negotiated credit terms with major domestic market customers across India. The product enjoys swift order processing, reinforced packaging, and timely delivery to rice mills, processing plants, and distributors nationwide, ensuring reliable supply and competitive rates for all business partners.

Application and Usage Guidance

The Pneumatic Rubber Sheller is designed for use exclusively in dry and clean grain processing areas. Direction of use involves fitting the sheller roller into standard rice mill assemblies, enabling reliable dehusking and husk removal. Usage type is continuous, supporting demanding operational cycles in milling plants. Its area of application includes rice mills, grain processing factories, and agro-industrial environments requiring optimized rice grain handling for superior yield and quality.

FOB Port, Payment, and Domestic Shipping Details

All shipped goods are dispatched from major Indian FOB ports. Shipment rates are determined by quantity, packaging choice, and consignment size. Payment terms include advance payment or negotiated credit terms with major domestic market customers across India. The product enjoys swift order processing, reinforced packaging, and timely delivery to rice mills, processing plants, and distributors nationwide, ensuring reliable supply and competitive rates for all business partners.

FAQs of Pneumatic Rubber Sheller:

Q: How is the Pneumatic Rubber Sheller installed in rice mills?

A: The sheller is engineered for easy fitting with standard sheller assemblies, allowing quick installation without specialized tools. Its cylindrical design ensures compatibility with most pneumatic rice sheller machines.Q: What benefits does the Pneumatic Rubber Sheller offer in operational efficiency?

A: Its wear-resistant surface and optimized grip deliver efficient dehusking, while low noise levels and long roller life expectancyup to 5,500 operational hoursreduce maintenance frequency and downtime in rice mills.Q: Where should the Pneumatic Rubber Sheller be used for best results?

A: For optimal performance, use the sheller in dry and clean grain processing environments such as rice mills and grain factories, where its abrasion resistance and thermal stability maximize service life.Q: How does shipment and payment work for domestic customers in India?

A: Goods are shipped from main FOB ports with rates determined by order size and packaging. Payment terms are flexible, including advance payment or credit arrangements for established domestic clients within India.Q: What components are included with the Pneumatic Rubber Sheller?

A: Each unit comes with a roller body, rubber covering, and end flanges, designed to operate at up to 1,500 rpm and withstand high abrasion and tear, ensuring robust shelling operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Rubber Sheller Category

Vibro Pneumatic Rubber Sheller

Minimum Order Quantity : 1 , , Piece

Hardness : 655 Shore A

Product Type : Rubber Sheller

Compression Ratio : Superior compression ratio for even shelling

Tensile Strength : High tensile rubber for long life

Part Type : Shelling Roll

Manual Rubber Sheller

Minimum Order Quantity : 1 , , Piece

Hardness : Medium

Product Type : Rubber Sheller

Compression Ratio : Optimized for rubber shelling efficiency

Tensile Strength : High, suitable for agricultural use

Part Type : Manual Sheller

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS