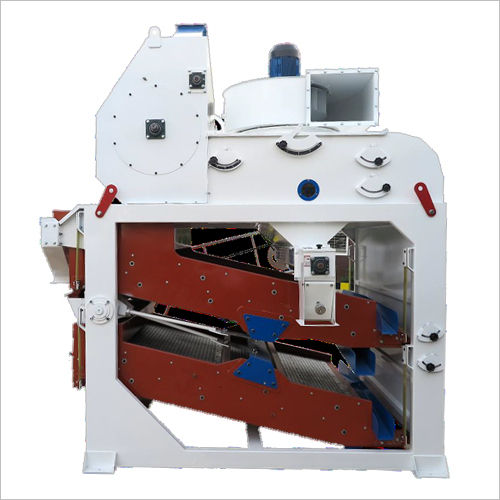

Vibro Paddy Cleaner

Vibro Paddy Cleaner Specification

- Material

- Stainless Steel

- Computerized

- Yes

- Capacity

- 4-8 T/hr

Vibro Paddy Cleaner Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Vibro Paddy Cleaner

Suitable for:

Salient features:

No moving parts low maintenance

Specifications:

| Model No. | VPC 80 | VPC 100 | VPC 125 | VPC 150 | |

| Capacity on paddy, TPH | 3 - 4 | 5 - 8 | 8 - 12 | 12 - 16 | |

| Power HP Qty. | Machine (Vibro motor) | 0.5 - 2

| 0.5 - 2 | 0.5 - 2 | 0.75 - 2 |

|

| Blower (2880) | 5 - 1 | 7.5 - 1 | 10 - 1 | 10 - 1 |

| Aspiration CMM | 50 | 70 | 85 | 100 | |

| Screen area in Sq. M.

| 3 | 4 | 5 | 6 | |

| Overall dimension LxBxH mm | 2400 x 1400 x 1800 | 2700 x 1600 x 1800 | 2700 x 1850 x 1800 | 2700 x 2100 x 1800 | |

| Weight in Kgs. (approx.) | 650 | 750 | 900 | 1100 | |

| Foundation dimension in mm L x W (Dia - 18, 4 holes) | 1345 x 1364 | 1645 x 1290 | 1645 x 1490 | 1645 x 1790 | |

Efficient Vibrating Sieve Technology

Our Vibro Paddy Cleaner uses vibrating sieve technology to enhance the separation of impurities from paddy grains. The result is a cleaner product and improved efficiency in downstream processing, making it a valuable solution for modern agricultural and food processing operations.

Smart Computerized Control System

Integrated computerized controls allow for precise operation, ensuring optimal performance and easy monitoring. This automation streamlines grain cleaning, reduces manual intervention, and delivers consistently high-quality output.

Robust Stainless Steel Construction

Fabricated entirely from stainless steel, the Vibro Paddy Cleaner offers exceptional durability and corrosion resistance. This construction promotes hygiene and is suitable for strict food safety environments, ensuring longevity and dependable service.

FAQs of Vibro Paddy Cleaner:

Q: How does the Vibro Paddy Cleaner improve the paddy cleaning process?

A: The Vibro Paddy Cleaner utilizes a vibrating sieve mechanism combined with computerized controls to efficiently remove dust, debris, and impurities from paddy. This results in higher cleaning accuracy and better grain quality, reducing manual labor and processing time.Q: What is the capacity range of the Vibro Paddy Cleaner?

A: This machine can process between 500 kg/hr to 8 tons/hr, making it suitable for both medium and large-scale grain cleaning operations.Q: When should I use a Vibro Paddy Cleaner in my grain processing line?

A: The Vibro Paddy Cleaner is ideally used at the initial cleaning stage to ensure that only pure, high-quality grains proceed to further processing, thereby safeguarding equipment and enhancing overall efficiency.Q: Where can the Vibro Paddy Cleaner be installed?

A: This cleaner is suitable for installation in rice mills, grain processing plants, and agri-food industries. Its compact design and stainless steel construction make it versatile for diverse operational settings.Q: What are the operational benefits of the computerized system?

A: The computerized system offers precise control over cleaning parameters, automatic adjustments, and easy monitoring, which leads to consistent cleaning outcomes and streamlined productivity.Q: How do I maintain the Vibro Paddy Cleaner for optimal performance?

A: Regular cleaning of the sieve, checking for wear on moving parts, and adhering to manufacturer-recommended maintenance ensures efficient and long-lasting operation of the machine.Q: What advantages does stainless steel construction provide?

A: Stainless steel resists corrosion and contamination, is easy to clean, and withstands heavy-duty use, making the Vibro Paddy Cleaner dependable for maintaining food safety and hygiene standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paddy Cleaner Category

Single Deck Paddy Cleaner

Minimum Order Quantity : 1 Piece

Computerized : Yes

Material : Stainless Steel

Capacity : 48 T/hr

Type : Single Deck Paddy Cleaner

Automatic Grade : Automatic

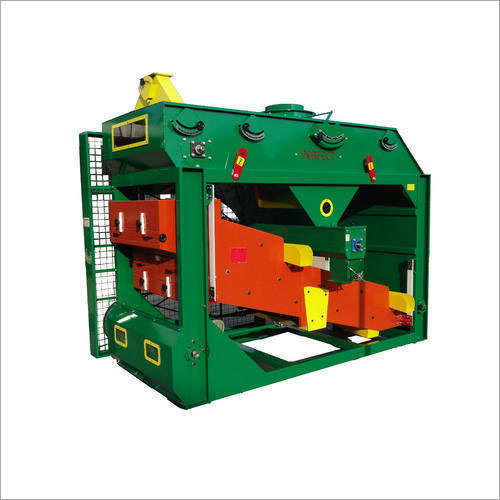

Double Deck Paddy Cleaner

Minimum Order Quantity : 1 Piece

Computerized : Yes

Material : Stainless Steel

Capacity : 48 T/hr

Type : Double Deck Paddy Cleaner

Automatic Grade : Automatic

Combined Paddy Cleaner

Minimum Order Quantity : 1 , , Piece

Computerized : Yes

Material : Stainless Steel

Capacity : 12 T/hr

Type : Combined Paddy Cleaner

Automatic Grade : Automatic

Single Deck Paddy Pre Cleaner

Minimum Order Quantity : 1 , , Piece

Computerized : Yes

Material : Stainless Steel

Capacity : 48 T/hr

Type : Paddy Pre Cleaner

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS