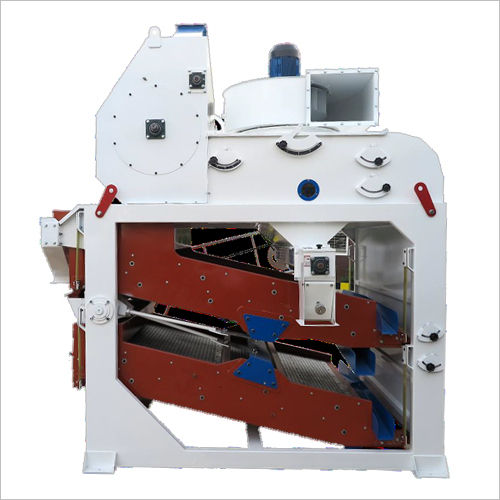

Combined Paddy Cleaner

Combined Paddy Cleaner Specification

- Type

- Combined Paddy Cleaner

- Material

- Stainless Steel

- Capacity

- 4-8 T/hr

- Computerized

- Yes

Combined Paddy Cleaner Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Combined Paddy Cleaner

Joined Paddy Cleaner is a blend of both pre-cleaner and De-stoner, which spares a machine and a lift. Since every one of the openings are fixed appropriately, there is no residue around the machine when being used. Our inside and out information about changed industry factors has supported up our image name to assess with dependability and genuineness. We deal with the whole generation process according to fluctuated modified and institutionalized details. We offer this item in the most sensible estimating accessible in the market.

Technical Specifications

|

Automation Grade |

Automatic |

|

Brand |

Perfect Equipments |

|

Capacity |

6.5 - 7.5 Tonnes |

|

Material |

Stainless Steel |

|

Power |

2.2 kW |

Effortless Paddy Cleaning Experience

Our Combined Paddy Cleaner integrates advanced computerized controls and an automatic grade system to deliver seamless operation. The robust stainless steel construction ensures long-term reliability, even in demanding environments. Its modern design maximizes throughput while maintaining excellent cleaning efficiency, making it indispensable for large and small rice processing facilities.

Versatile Capacities for Diverse Needs

Designed to accommodate different volumes, the cleaner offers capacities of 1-2 T/hr and 4-8 T/hr, supporting a wide range of processing scales. This adaptability allows rice millers to optimize their workflow and invest with confidence, knowing their equipment can evolve with business growth and market demands.

FAQs of Combined Paddy Cleaner:

Q: How does the Combined Paddy Cleaner enhance the cleaning process of rice grains?

A: The Combined Paddy Cleaner employs advanced automated and computerized mechanisms to effectively separate impurities from paddy, ensuring superior grain cleanliness with minimal human intervention. Its consistent cleaning process leads to improved rice quality and higher output rates.Q: What are the main benefits of using a stainless steel paddy cleaner in grain processing?

A: Utilizing high-grade stainless steel provides excellent resistance to rust and wear, extending machine life and reducing maintenance requirements. This also ensures that food safety standards are upheld during the cleaning process, delivering clean rice for end consumers.Q: When is it ideal to use this type of paddy cleaner in a rice mill operation?

A: The Combined Paddy Cleaner is best deployed at the initial stage of rice processing after harvesting, effectively removing straw, stones, and dust before milling. Its automatic operation ensures continuous and uninterrupted workflow in busy processing plants.Q: Where can this computerized and automatic grade paddy cleaner be installed?

A: With its compact dimensions (2950x1550x1800 mm), the cleaner can be easily installed in rice mills, grain warehouses, and agro-processing centers that have modern infrastructure. Its streamlined design also facilitates maintenance and operation in busy industrial settings.Q: What is the typical usage process for this combined cleaner?

A: Operators load harvested paddy into the machine, then configure settings via the computerized interface. The system automatically regulates cleaning parameters, separating foreign matter from grains, and collecting cleaned paddy for further milling.Q: How do users benefit from the automatic and computerized features of this machine?

A: Automation reduces labor needs and human error, while computerized controls allow for easy monitoring and adjustments, ensuring consistent cleaning performance and efficient operation throughout long production runs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

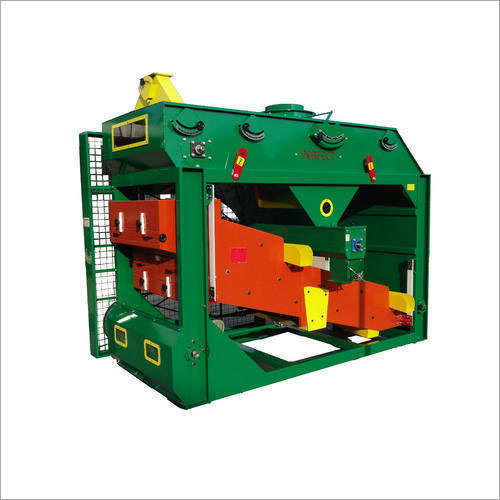

More Products in Paddy Cleaner Category

Double Deck Paddy Cleaner

Minimum Order Quantity : 1 Piece

Capacity : 48 T/hr

Computerized : Yes

Material : Stainless Steel

Type : Double Deck Paddy Cleaner

Automatic Grade : Automatic

Single Deck Paddy Cleaner

Minimum Order Quantity : 1 Piece

Capacity : 48 T/hr

Computerized : Yes

Material : Stainless Steel

Type : Single Deck Paddy Cleaner

Automatic Grade : Automatic

Single Deck Paddy Pre Cleaner

Minimum Order Quantity : 1 , , Piece

Capacity : 48 T/hr

Computerized : Yes

Material : Stainless Steel

Type : Paddy Pre Cleaner

Automatic Grade : Automatic

Vibro Paddy Cleaner

Minimum Order Quantity : 1 , , Piece

Capacity : 48 T/hr

Computerized : Yes

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS