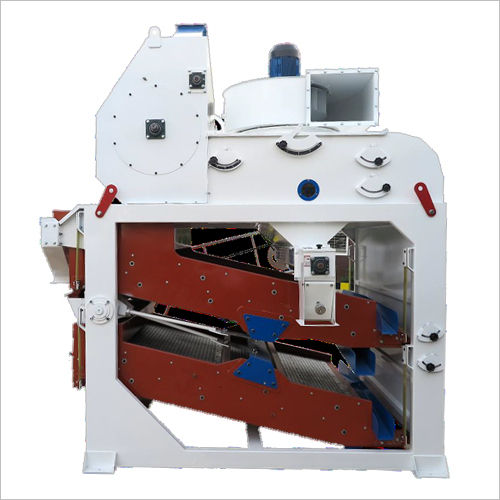

Single Deck Paddy Cleaner

MOQ : 1 Piece

Single Deck Paddy Cleaner Specification

- Type

- Single Deck Paddy Cleaner

- Material

- Stainless Steel

- Capacity

- 4-8 T/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Sorting Efficiency

- 99%

- Size

- Standard

- Width

- Customizable

- Weight

- Approx. 850 kg

- Dimension (L*W*H)

- 2600 x 1500 x 1700 mm

- Motor Power

- 3 HP

- Installation Type

- Floor Mounted

- Surface Finish

- Polished

- Application

- Paddy, Rice Cleaning

- Mobility

- Fixed

- Noise Level

- Low

- Screen Material

- High Tensile Steel

- Frequency

- 50/60 Hz

- Power Source

- Electric

- Voltage

- 220-380V

Single Deck Paddy Cleaner Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Week

About Single Deck Paddy Cleaner

Single Deck Paddy Cleaner is intended for thorough cleaning of grains at the intake stage. The machine is designed to remove all big impurities, straws, fine sand, immature paddy etc. It is used for sieving paddy and other grains to make them free of dust, small stones, paddy hulls and short straws (remove both big & small impurities from the raw grain). It can separate large, small and light impurities from wheat, paddy, corn and oil bearing materials. The offered Single Deck Paddy Cleaner is very efficient and made for commercial uses. It is easy to maintain and operate.High-Efficiency Paddy Cleaning

This Single Deck Paddy Cleaner is engineered to provide exceptional sorting performance, thanks to its robust construction and advanced automatic system. With an impressive 99% sorting efficiency and computerized controls, it ensures that your paddy or rice is cleaned to the highest industry standards. The use of high tensile steel screens further guarantees longevity and reliability, saving you time and effort in the cleaning process.

Customizable and Robust Design

Constructed from premium stainless steel, this machine offers a customizable width to fit diverse operational requirements. Its polished surface ensures easy cleaning and minimal maintenance. The floor-mounted, fixed design provides stability during operation, while the compact dimensions fit seamlessly within most standard industrial settings. This cleaner stands out for its durable build, ensuring years of trouble-free use.

FAQs of Single Deck Paddy Cleaner:

Q: How does the Single Deck Paddy Cleaner work to clean paddy and rice?

A: The Single Deck Paddy Cleaner utilizes a high tensile steel screen that vibrates to separate debris, dust, and unwanted particles from paddy and rice. The automatic computerized system regulates the cleaning process, ensuring a thorough and efficient output suitable for industrial needs.Q: What are the main benefits of using this paddy cleaner in a rice mill?

A: The primary benefits include high sorting efficiency of up to 99%, minimal operational noise, low maintenance due to its sturdy construction, and swift cleaning capabilities processing 4-8 tons per hour, all contributing to improved output quality and reduced workload.Q: When should I use the Single Deck Paddy Cleaner during rice processing?

A: You should operate the paddy cleaner at the initial stage of rice processing, before milling, to remove impurities and ensure that only clean grains proceed to the next phase. This helps in protecting other machinery and improving the final product quality.Q: Where can this machine be installed within a rice processing plant?

A: Designed as a floor-mounted and fixed unit, the paddy cleaner is best installed in the pre-cleaning section of a rice mill or grain processing facility. Its standard size and customizable width ensure adaptability to various plant layouts.Q: How is the machine powered, and what electrical requirements does it have?

A: The cleaner operates on a 3 HP electric motor and is compatible with 220-380V, 50/60 Hz power supplies. Its suited for typical industrial electrical installations, making it efficient and easy to integrate into existing setups.Q: What sets this paddy cleaner apart from other cleaning machines?

A: This model distinguishes itself with a polished stainless steel build, high tensile steel screens, automatic and computerized operation, low noise emission, and an impressive 99% sorting efficiency, offering reliability and top-tier performance for rice mills.Q: Can the width of the paddy cleaner be adjusted for specific needs?

A: Yes, the width of this machine is customizable according to your operational requirements, ensuring a perfect fit for different production capacities and facility spaces.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paddy Cleaner Category

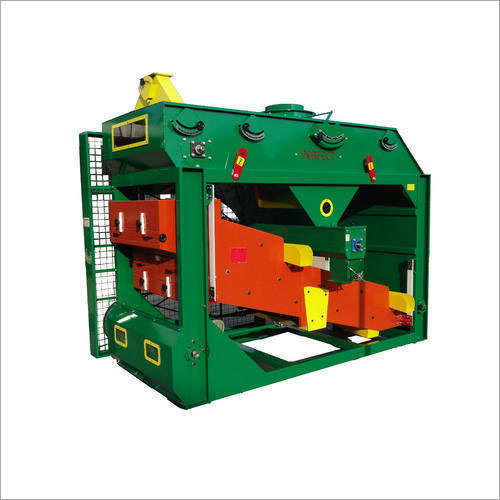

Double Deck Paddy Cleaner

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Type : Double Deck Paddy Cleaner

Capacity : 48 T/hr

Computerized : Yes

Automatic Grade : Automatic

Combined Paddy Cleaner

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Type : Combined Paddy Cleaner

Capacity : 12 T/hr

Computerized : Yes

Automatic Grade : Automatic

Single Deck Paddy Pre Cleaner

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Type : Paddy Pre Cleaner

Capacity : 48 T/hr

Computerized : Yes

Automatic Grade : Automatic

Vibro Paddy Cleaner

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Type : Vibrating Sieve

Capacity : 500 Kg/hr

Computerized : Yes

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS